CCI

| 840G

Specifications

- Valve size

- 1/2" to 24"

- Ratings

- ANSI Class 150, 300, 600, 900, 1500 ,2500 and 4500

- End connections

- RF, SW, BW, RTJ

- Materials

- A216 WCB, WCC A217 WC6, WC9 A351 CF8(M), CF3(M), CN7M A351 Duplex, B148 Al-Br A352 LCB, LCC HASTELLOY-B/C

- Flow Characteristic

- Equal Percentage, Linear or Quick Open.

- Seat Leakage

- Standard-ANSI Class IV Option-ANSI Class V or VI

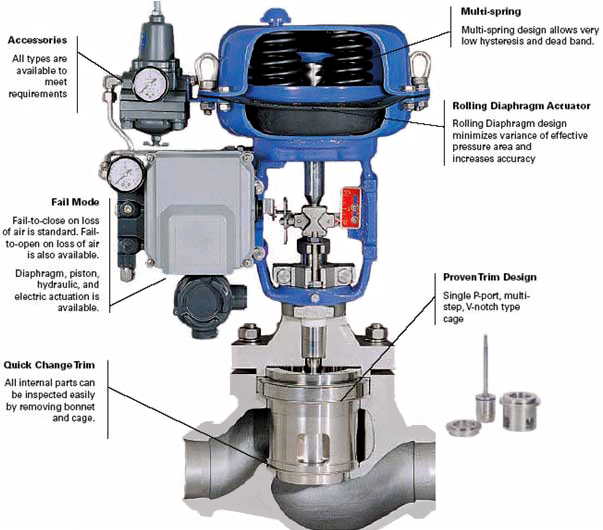

The series 840G Cage-guided valve is specially designed using the most recent refinements in control valve technology. It is used to control a wide variety of relatively clean liquids and gases at high-pressure differentials. The design of the 840G valve is very flexible in that it allows a variety of trim types to be installed in the body. In addition, its cage-guided construction reduces plug vibration and provides stable performance throughout travel. All trims of the 840G valve have a quick change design so it guarantees convenient repair and easy replacement of trim. The 840G valve is available in size 1/2"~24" ANSI 150~4500 classes, with either flanged or welding end connections.

Features

Simple-to-Change Capacity or Characteristic

A simple cage change is all that is required to change between reduced and full-sized capacity trims or between linear and equal percentage characteristics.

Tight Shutoff

A variety of shutoff classes from ANSI IV through VI are available to meet application requirements.

Sour Gas/Corrosive Fluid Capable

The wide choice body and trim materials allows the 840G to be applied to corrosive/sour gas services with full compliance to NACE requirements.

Easy Maintenance

Top -entry design and a cage-retained seat ring allow for quick inspection or trim change.